|

||

| Design Optimization Expert System | ||

|

||

|

||

|

||

| Free |

|

Free |

And ANSYS Workbench Model Optimization Part 3: Results of the DOES Optimized Model Download the complete Case Study here (PDF) |

|

|

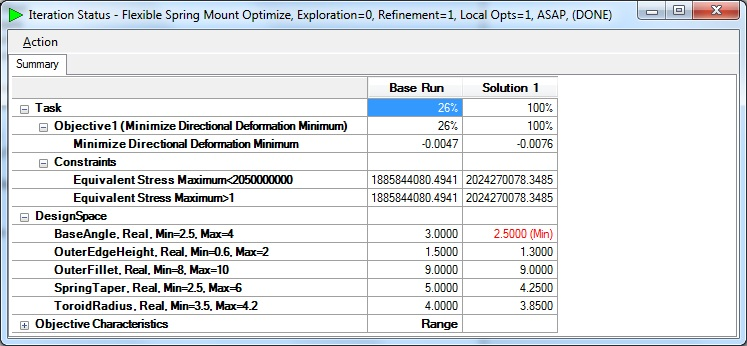

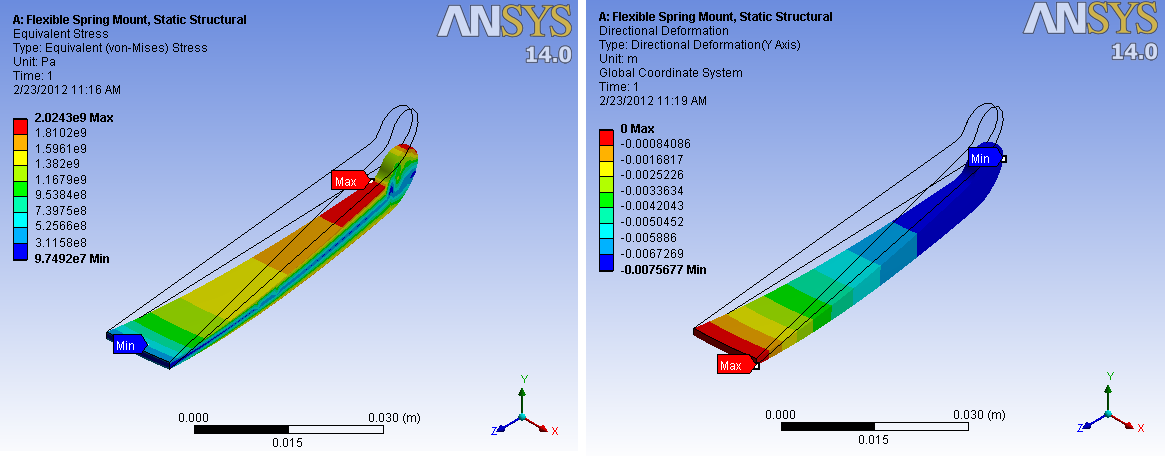

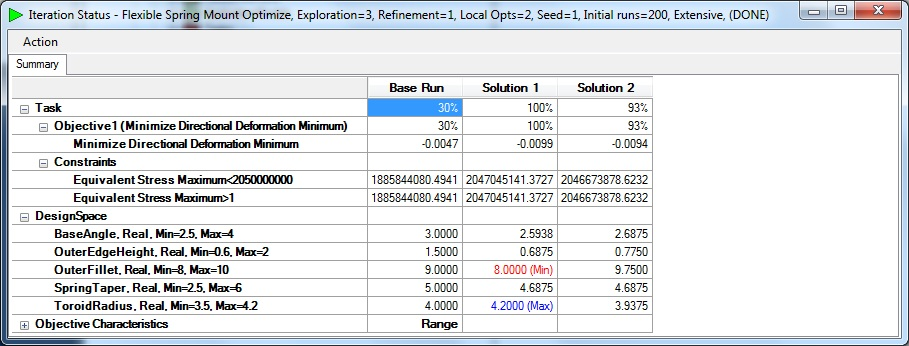

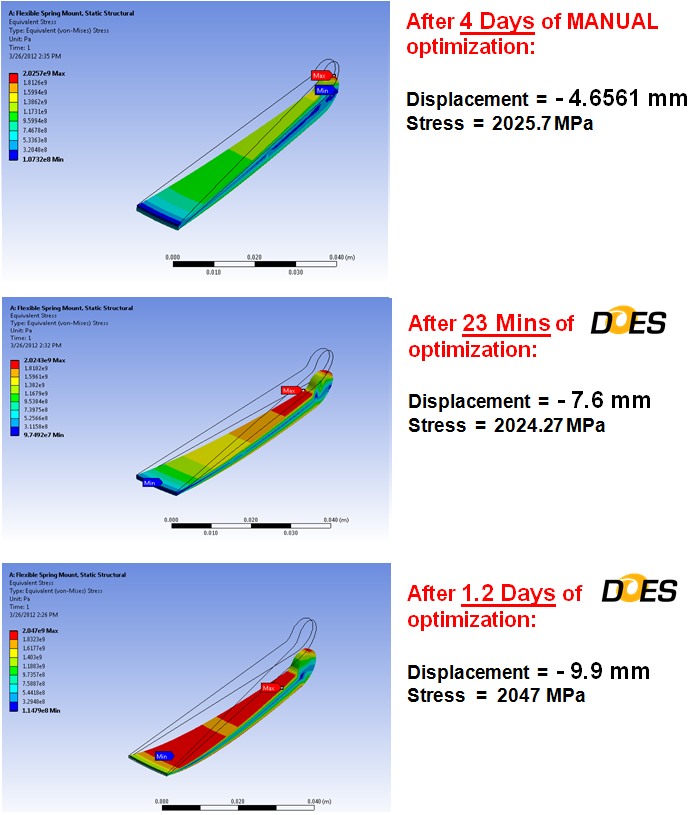

The first Iteration of this Expert Design improved the mount’s deflection by 65% allowing a deformation of

-7.6 mm, with a maximum equivalent stress of 2024.270078 MPa, which was about 24 MPa less

than the maximum allowed. |

|

|

Return to DOES Home Page |

|