|

||

| Design Optimization Expert System | ||

|

||

|

||

|

||

| Free |

|

Free |

And ANSYS Workbench Model Optimization Part 2: Optimizing with DOES Download the complete Case Study here (PDF) |

|

|

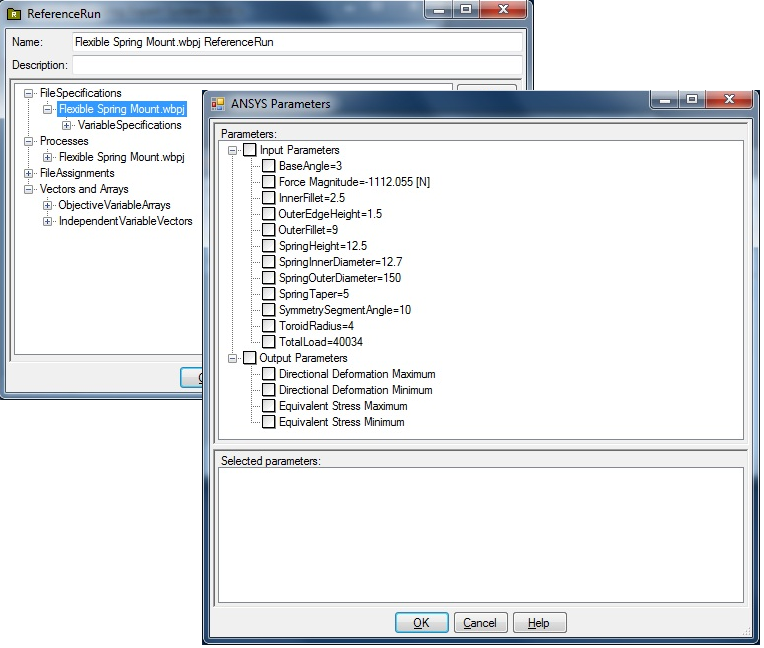

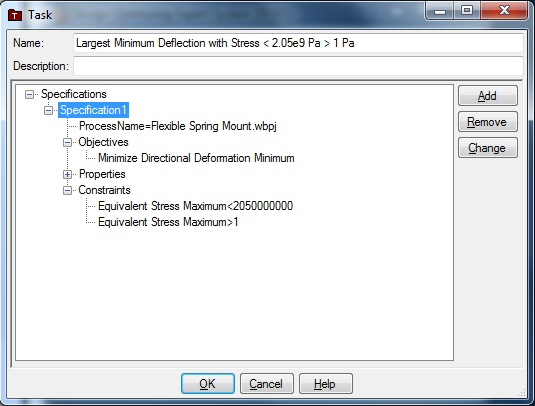

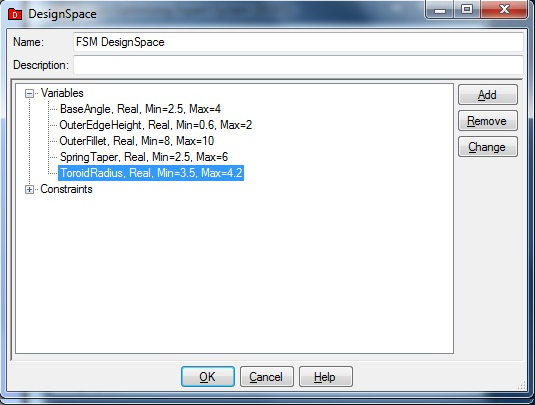

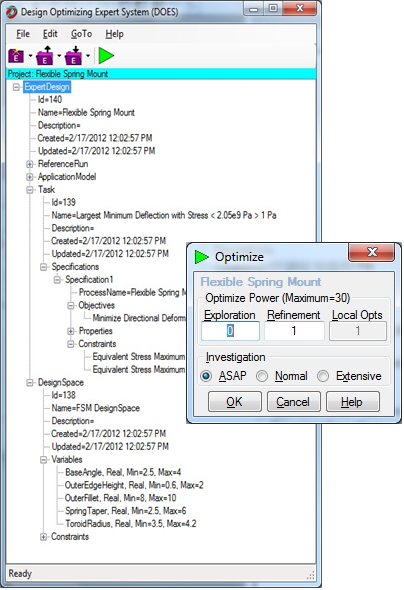

To optimize any model with DOES one must first use its Knowledge Engineering user interface to create an Expert Design.

The Expert Design defines the objectives and constraints and the model parameters that can be varied to create

optimized designs. Using DOES' intelligent ANSYS tool partner interface, the process of loading information from the

Flexible Spring Mount ANSYS Workbench Project into the Reference Run of the Expert Design is easy. The tool partner

interface recognizes the type of model, automates many of the definition tasks and provides all of the input and

output variables associated with the ANSYS model. |

|

|

Once all of the desired input Design Space Variables have been specified, optimizations can be launched by clicking

on the Green Arrow to obtain improved designs. The Optimize dialog box controls the amount of computing that will

be performed to optimize the design which in turn determines how long the optimization will run and normally how good

the designs will be. The default Optimize parameters, shown in the box to the left were used to obtain the initial results for this study. Exploration Power – determines the level of the Design of Experiments (DoE) that DOES uses during the 1st stage, of the optimization process. If it is not zero, DOES uses its proprietary DoE algorithms to locate the most promising solution areas within the design space. If it is zero, NO exploration is performed. Refinement Power – is the number of levels of refinement that DOES applied to each Solution that was created during Exploration. Refinement is the second stage of the optimization process. Local Opts – determines the number of improved designs that DOES will attempt to create. The first Local Opt is the best new design. The second Local Opt is the second best design, etc. |

|

Page 3: Results of the DOES Optimized Model -> |

|

|